Pen injector engine

A growing challenge, a flexible response

In the modern era, self-administration of drugs is a growing trend.

In this evolving context, CB Automation stands as a partner of excellence for the design and production of machines for the assembly and testing of pen injectors.

Our innovative proposals respond to the growing needs of an increasingly sophisticated market, offering a wide range of fl exible solutions.

Challenge

A leading global drug delivery solution provider wanted to evaluate different engine for pen injector models on the market to understand industry needs and trends.

It approached us with two different models for assembly, characterised by signifi cant differences, especially in the number of components required for assembly. The customer needed a

flexible, cost-optimized and compact assembly solution to meet the footprint.

Solutions

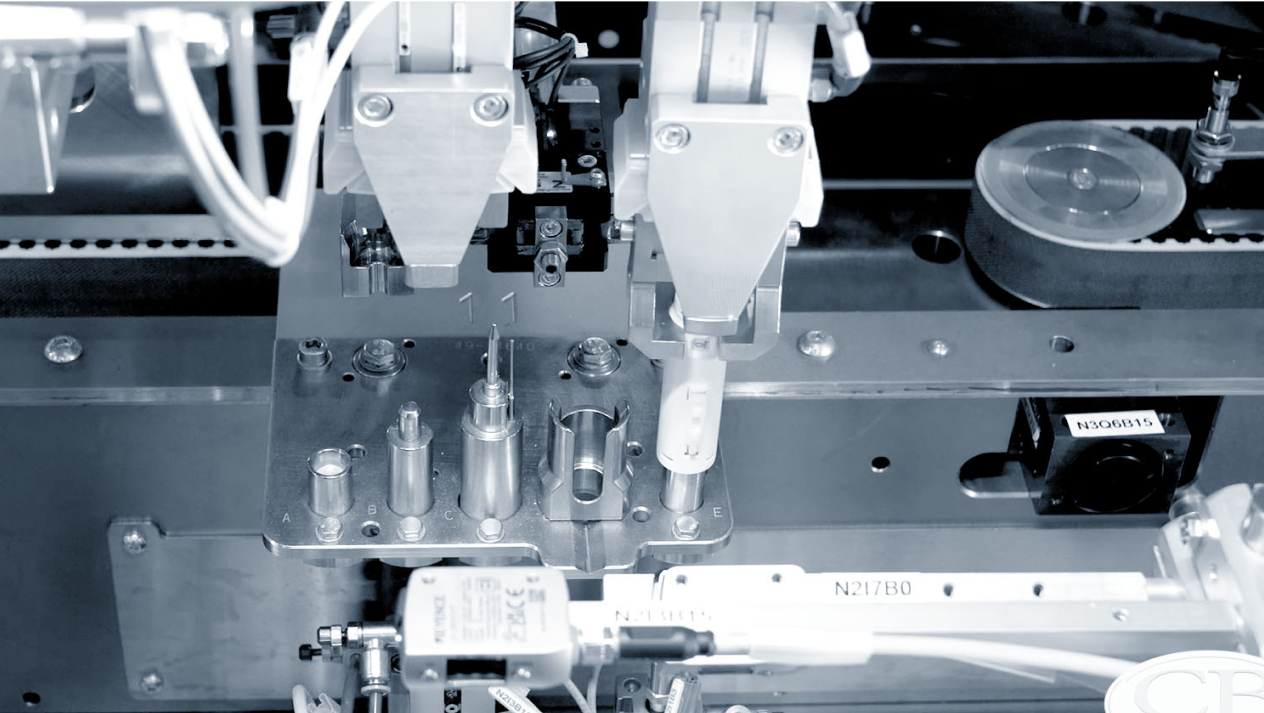

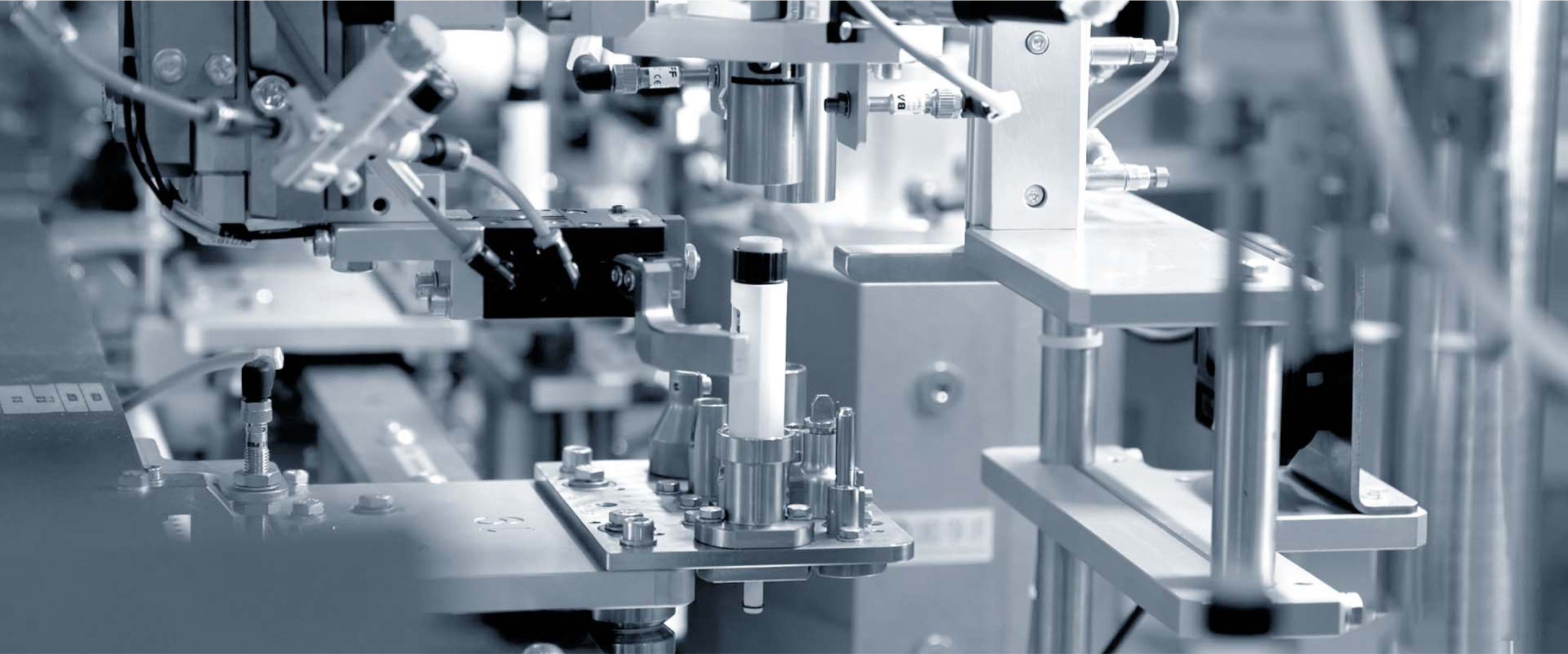

CB Automation proposed a semi-automated assembly solution, where some loadings, force, coupling, functionality and vision quality checks are entrusted to fully automatic stations, while operators handle manual component loading.

The assembly machine is designed on a linear base chassis, using a flexible conveyor belt with free pallet, which enhanced overall productivity, flexibility and optimize the footprint. The manual loading stations are ergonomically designed and equipped with automatic controls, that guarantee the safety of the operators and of the process during work.

The automatic stations are equipped with state-of-theart technologies to support with precision and all the in-process controls necessary for the perfect product assembly.